Grist Analytics

Partnership

The ultimate software solution to optimize your brewery's fermentation.

We're teaming up with Grist Analytics to provide brewers with top data management for their brewhouses and cellars. Grist Analytics is a fast and intuitive software that collects, stores, and analyzes production data.

You can make efficiency, performance, and quality-based decisions in real time from data taken from the brewhouse through the packaging!

Tank time is money, and optimizing your brew performance should be a top priority.

What is Grist Analytics?

Grist Analytics is a customizable, intuitive software solution which helps you collect and analyze brewhouse data. We've partnered with them to make it easier for you to track your fermentations and get real-time alerts if something is amiss.

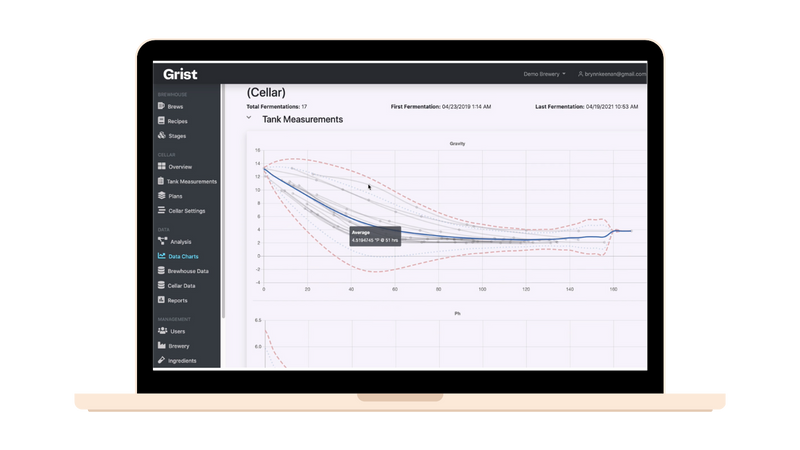

That binder full of brewsheets in your office isn't very searchable, and that ERP you're using is really built with your bookkeeper in mind. With Grist Analytics, you can see how your fermentations are performing compared to historical averages at-a-glance, tease out trends in your brewery's history, and easily see if a beer is out of spec as soon as a problem arises.

In partnership with Grist Analytics, we can help you track yeast performance through successive generations, too, and help guide your decisions on repitching.

GRIST Analytics x Escarpment Labs

How can this partnership help you meet your goals?

We want to give you the tools to make the best quality product - and ultimately saving money in the long run. This partnership will enable you to share your data with Escarpment Laboratories so our team of fermentation experts can give you the advice you need to maximize your brewery's efficiency and get the most out of your yeast.

• Access to expertise and feedback from Escarpment Laboratories

• Deals on Escarpment Laboratories products

• Data driven results to help steer spending decisions for better ROI

• Customizable to fit your operation

Easily compare yeast generations

View historical fermentation curves for every beer you make and easily isolate variables that affect fermentation speed and performance.

Pearce Fleming, Commonhouse Aleworks

Grist takes a lot of data, and puts it in a very easy to use format, for people that are not spending all day in spreadsheets. I can see issues as they are happening, not after 10 batches.

Ewan Muir, Annex Ales

What became apparent at the outset was that the presentation of our cellar data in a user-friendly visual manner with clear and obvious trendlines and base data was integral to us noticing outliers among our datasets. And as the old adage goes, the first step in solving an issue is recognising there is one.

Used in combination with consistent yeast pitches from Escarpment Labs, we are able to track and monitor our yeast's performance in order to maximise the yeast performance over time and throughout generations, and accurately predict the longevity and performance of our cultures.

Nicole Steinhilber, Craft Solutions

Grist Analytics has changed the game of the process control. As a brewing scientist I have relied heavily on building and manipulating my own spreadsheets for years. Having one platform inclusive of data from the brewhouse through fermentation and packaging with analytical capabilities provides major time savings, and is valuable to process improvements for my clients.

This program is the most superior option for brewing software in the market and I can't recommend it enough.

Case study

Overall, Commonhouse aleworks saw:

- 65% reduction in fermentation time

- 50% reduction in fermentation variation

- 50% increase in attenuation consistency

But, how?

Commonhouse is a rapidly growing brewery who was cranking out beer to keep up with demand when they started having fermentation issues with their IPA. As the owner, Pearce, puts it;

"We were experiencing hop creep in our best-selling beer at a rate that was going to choke off our ability to grow without massive financial investment.”

Grist was recommended to analyze and democratize their cellar data to facilitate root cause analysis. Once ownership and production were looking at the same digestible information, it became clear where areas of inconsistency were leading to slow fermentations and hop creep.

CASE STUDY

What did they change?

Consistency and timing of dry hopping. Dry hopping is often done when the schedule

allows, rather than the optimal time for mitigating hop creep. Commonhouse began

scheduling these events based on gravity rather than time. See hop creep blog post.

Increasing consistency in the brewhouse. In several Grist studies brewhouse pH has been

correlated to fermentation performance. Commonhouse began consistently hitting the

optimal pH range for yeast health.

Optimizing yeast strain for hop creep. Commonhouse made sure they were using yeast that could handle rapid fermentation, warm cropping, and hop creep.

Consistency and timing of yeast harvest. Research shows that warm harvesting increases fermentation performance over traditional cold harvesting. In addition, dry hopping

significantly reduces yeast viability and performance. Commonhouse took these into consideration when building an appropriate harvesting schedule based on gravity.

Within 3 months Commonhouse reduced its fermentation time by 170hrs, and increased consistency across the board. The team at Commonhouse continues to make good beer more efficiently everyday.

“Grist has created a data driven culture and conversation around other tweaks we can

make to produce the same quality beer at higher throughput in every aspect from grain to glass.” - Pearce Fleming

Packaging & pricing

Did we mention there are exclusive Escarpment Labs perks with our partnership?

FREQUENTLY ASKED QUESTIONS

1. I already have an ERP system, why do I need Grist Analytics?

Grist Analytics is not an ERP solution. 80% of Grist Analytics users use the software along side an ERP system. ERP systems are generally for tracking inputs and outputs and financial considerations across operations.

Grist Analytics is a tool for storing brewhouse, cellaring and packaging logs and providing analytical reports that help find efficiencies, and provide solutions to improve operations and ultimately the finished product.

2. Can Grist Analytics be customized to fit the operations of my brewery?

Yes, there are a number of customizations that can be implemented to fit your needs. Grist Analytics will work with you to help implement the software so you can change the software to fit your needs rather than have to change your process to fit the way the software works.

3. Can Grist Analytics help with my ingredients traceablity?

Yes, Grist Analytics can help you track ingredients and lot numbers across batches and provide you quick access to see where a specific lot was used. This can also help with identifying unexpected results and point to what ingredient may have contributed to those results.