All About Attenuation

To many brewers, yeast attenuation is a bit of a mysterious black box. Yeast producers provide wide ranges in their product specs. Even more confusingly, sometimes the yeast in your fermentation performs above or below that range. That is understandably frustrating, and leads to a lot of troubleshooting conversations here at Escarpment Labs!

We’re here to try to demystify yeast attenuation and help you understand how to dial in attenuation in your beers. This is especially important when working with the 2021 North American barley crop which may present atypical results in your brewhouse and cellar.

We want to give brewers the data and knowledge needed to be able to hit their targets, acknowledging that attenuation is a really tough one to hit perfectly since everyone's malt and brewhouse is different. Yeast is only one variable of many!

Key factors in beer attenuation

Mashing is the primary control we have for attenuation because mashing determines the types of sugars we make available for our yeast to ferment.

Malting is also important. Some malts are higher in unfermentable melanoidins than others. Beyond that, malt is an agricultural product. While maltsters do an amazing job of keeping it consistent, malt can vary from year to year and location to location.

Yeast genetics are also critical. Some yeasts ferment some malt sugars poorly and will never be highly attenuative without help. Simply put, some yeasts don't have the required machinery to ferment some malt sugars. On the other hand, some yeasts are diastatic and will ferment nearly all available sugars and dextrins.

Yeast health and fermentation consistency is the final critical factor. Unhealthy yeast is at risk of stalling (incomplete ferment), especially when it is trying to get through the last of the sugar in the wort - maltotriose. Insufficient wort oxygenation is a common cause of stalled ferments. Temperature swings can also impact attenuation since cold temperatures can make yeast flocculate prematurely.

Mashing is the key driver of attenuation

In general, the sugar composition of wort is about 10-15% monosaccharides (glucose and fructose), ~5% sucrose, 40-60% maltose, 15-25% maltotriose, and 20-25% starches and dextrins (higher saccharides).

Your mashing choices as well as your base malt(s) will influence the type of sugars that end up in your wort and available to your yeast.

The malt itself has an influence. Factors such as the diastatic power (amount of enzymes) in the malt will influence how fermentable your wort is. This may vary from year to year as well, so malt is always an area to consider when troubleshooting attenuation changes.

Approximate temperature activity ranges for mashing enzymes. Adapted from How to Brew by Palmer.

Mashing also plays a key role. Mash rest temperature favours either alpha or beta-amylase, both of which have different consequences for the fermentability of your wort. For example, beta-amylase (favoured at lower mash temperatures) is capable of chopping up carbohydrate chains into maltose, but the enzyme activity takes longer than that of alpha-amylase. Alpha-amylase tends to work faster and can cleave carbohydrate chains in more places. The end result is that a long mash favouring beta-amylase (cooler temperatures) may contain higher maltose content and can be more fermentable. Most brewers aim for the middle of the two enzyme's activities, in the 145-152ºF range (63ºC-70ºC).

It is important to recognize that wort fermentability is a result of both time and temperature! The temperature determines which enzymes will be active, and the mash time gives them more or less opportunity to work. If you are aiming to make a very fermentable wort, our advice is to make sure you include a long mash rest at the low end of the temperature range (63-65ºC for at least 60 minutes), even if you are step mashing. Conversely, if you want to make a wort with low fermentability, we suggest mashing hotter for a shorter time (72-74ºC for 30 minutes). That will leave behind a higher proportion of unfermentable starches and dextrins in your wort.

Since mashing influences the types of sugars your yeast has access to, it will directly influence the attenuation potential of your yeast. In terms of yeast and fermentable sugars, there are certainly some differences between strains and families worth noting.

Some beer yeasts struggle to ferment maltotriose. For example, some kveik yeasts are poor at transporting and fermenting maltotriose, which means that kveik can sometimes underattenuate in standard wort. For kveik, it is helpful to make a maltose-rich wort to overcome this limitation. Other strategies include the lab evolution we did to make KRISPY 2.0, which is better at fermenting maltotriose.

We've leveraged poor maltotriose fermentation in other products like HYDRA, which brewers can use to leave some residual gravity in hazy IPAs in the face of hop creep-induced refermentation and astringency from high dry hopping rates.

English yeasts are famously very responsive to wort sugar composition. With some of our strains, you can get anywhere from 60 to 90% attenuation depending on what sugars are in the wort. English strains often leave some of the maltotriose behind, and like kveik, benefit from a maltose-rich wort to achieve high attenuations.

Yeast Lab Attenuation Ranges

At Escarpment Labs (and most yeast producers), the yeast products come with a stated attenuation range. In general, the range tends to be plus or minus 5% from the average attenuation observed in the average wort. This means that a strain with an average attenuation of 75% in the lab will typically be sold with a stated range of 70-80%. It doesn't mean that this yeast will only attenuate between 70-80%. Mashing and yeast health can influence attenuation below or above this range.

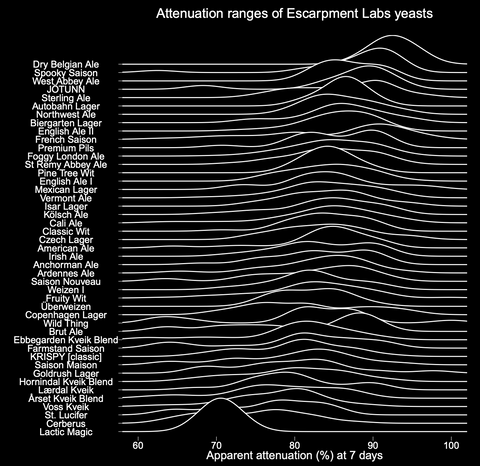

Over the last few years, we have recorded attenuation ranges for our yeast strains in a standardized, highly fermentable wort. This has helped us understand the typical attenuation ranges of our yeasts better. Plus, it looks cool when we plot it out a la Joy Division's Unknown Pleasures:

the unknown pleasures of attenuation (download pdf)

In general, diastatic yeasts are at the high end of the attenuation range, and kveiks are at the lower end, with workhorses like Cali in the middle.

Predicting and controlling attenuation

Okay, so we've explained some of the levers that control beer yeast attenuation. Now, how do we control and predict our attenuations better?

We have some tips below:

1. Do Forced Fermentations. The forced fermentation test is easy to do, and gives you very useful data. By doing a forced fermentation, you will know the attenuation potential of your yeast in your wort. This makes troubleshooting stalls later on much easier, as you will know the achievable attenuation or final gravity of your wort ahead of time.

2. Watch out when you switch base malts or when a new barley crop comes in. Sometimes you need to make a switch to a different base malt. Also, every year your malt supplier will phase in malt from a new growing season. When this happens, you need to consider the impact this change will have on your yeast and fermentations. Different malts have different enzyme content and activity, which may result in differences in wort sugar composition and attenuation. This is especially critical to watch for if you are distributing beer through retail channels where you must adhere to strict labelling margins of error (e.g. LCBO in Ontario).

3. Do pilot batches. This is especially important when trying a new yeast or a new malt. With a pilot batch, you will get a better sense of how the yeast, malt, and recipe you chose interact, and you can make sure your attenuation is better dialled in when you scale up or repeat your recipe.

4. Ask for help from your yeast and malt suppliers. Both are well versed in the technical nitty-gritty of wort production, and fermentation. You need to know that you are not alone and that your suppliers are always happy to help you when your attenuation values are unexpected or when you are trying out a new malt or yeast.

Curious about the attenuation for your yeast? You can find our range on any of our product pages.

Additional Resources:

- The Braukaiser wiki has some excellent resources on starch conversion and attenuation.

- John Palmer’s How To Brew is (as always) a fantastic resource for basic brewing science.

1 comment

This is really helpful content. I’ve been brewing for about ten years, but still need to pick the brains of experts all the time, so it is great that you guys take the time to impart your expertise in clear and informative articles like this one. Many thanks